Flowcate

Flowcate is a company passionate about geoinformatics, and positioning systems, and offers location-based software as a service that transforms location data into added value for users.

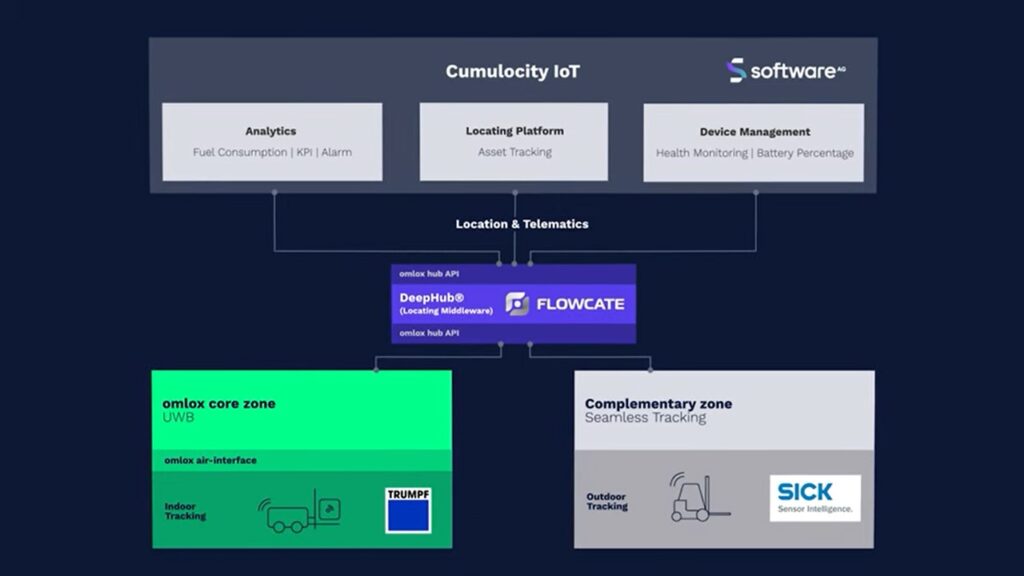

Solution – Asset Tracking with unified locating platform

The DeepHub® by Flowcate, is a locating-middleware that enables a seamless tracking of all moving things in intralogistics, like forklifts, palettes, equipment, and humans. It allows for an easy integration of all indoor positioning technologies – from all vendors – via a lightweight API. The DeepHub is compliant with the open locating standard omlox. Cumulocity consumes location-data and telemetry data via the DeepHub and visualizes real-time movements.

Challenges

- Easy access to location data indoors

- Integration of broad range of locating technologies and vendors.

- Vendor lock in with vertically integrated technology vendors

- Complex integration and not standardized data formats

- Seamless monitoring of equipment and optimization enabled by location data

Solution

- Cumulocity connected DeepHub via omlox-compliant API

- omlox & DeepHub offers homogenous data for business analytics

- Holistic overview of asset movements, energy consumption and much more

- Single omlox API to consume location data fused with telemetry data

Benefits

- No vendor dependency

- Saving of integration costs and resources

- Interoperability and flexibility among indoor locating hardware & software solutions

- Single, lightweight and standardized API Lower total cost of ownership

Contact

Contact Name: Dr. Matthias Jöst

Email: Matthias.Joest@flowcate.com

Website: Flowcate

Solution Assets